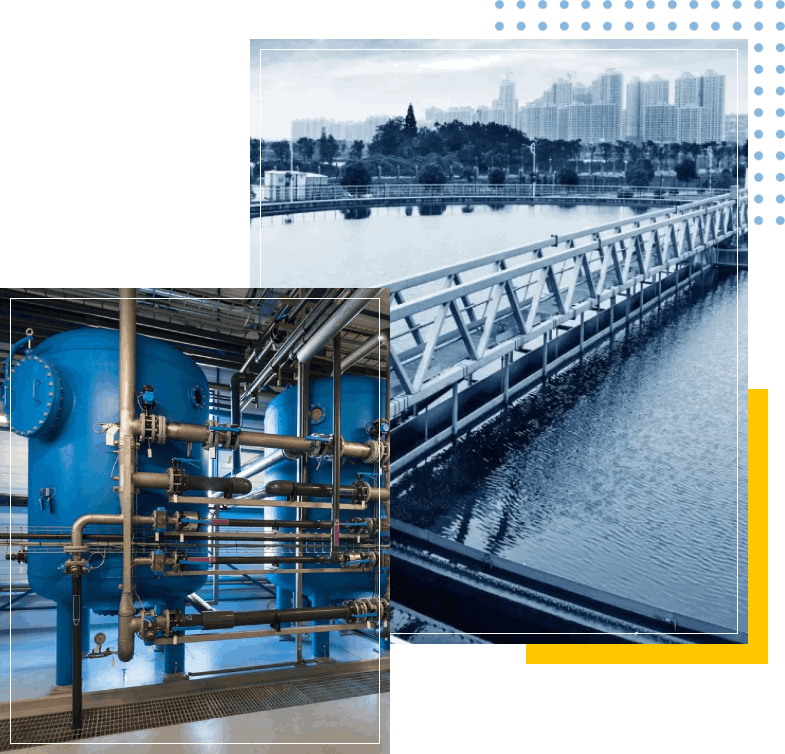

Aerated Membrane Bioreactor Solutions

The MBR represents an advanced version of the conventional activated sludge process, with PermaFlux UF modules replacing clarifiers. This evolution brings substantial enhancements, including superior effluent quality, increased biodegradation rates, a smaller footprint, reduced sludge production, and potential for reuse. MBR's excels in treating moderate-strength industrial wastewater, effectively removing organic pollutants and nutrients while retaining biomass within the bioreactor for consistently high-quality, clear, and pathogen-free effluent.

At Thetis Environmental, we provide the solution to the liquid-solid separation step, including taking the mixed liquor from the bioreactor, extracting clean water, and returning concentrated biomass to the bioreactor.